Nowadays, the application of mechanical equipment is very popular, and various industries have involved mechanical automation-related content.

For injection molding processors, “time is money”.

If want to improve plastic hangers production efficiency,

then must race against time, use higher-speed, more flexible, and higher-load robotic equipment to automate production, thereby improving the production efficiency.

The usage of manipulators for injection molding machines can cope with the challenges of high labor turnover,shortened lead times, and safe operation.

In addition, the robot can ensure the consistency of the operation cycle, improve the quality, and be more safe.

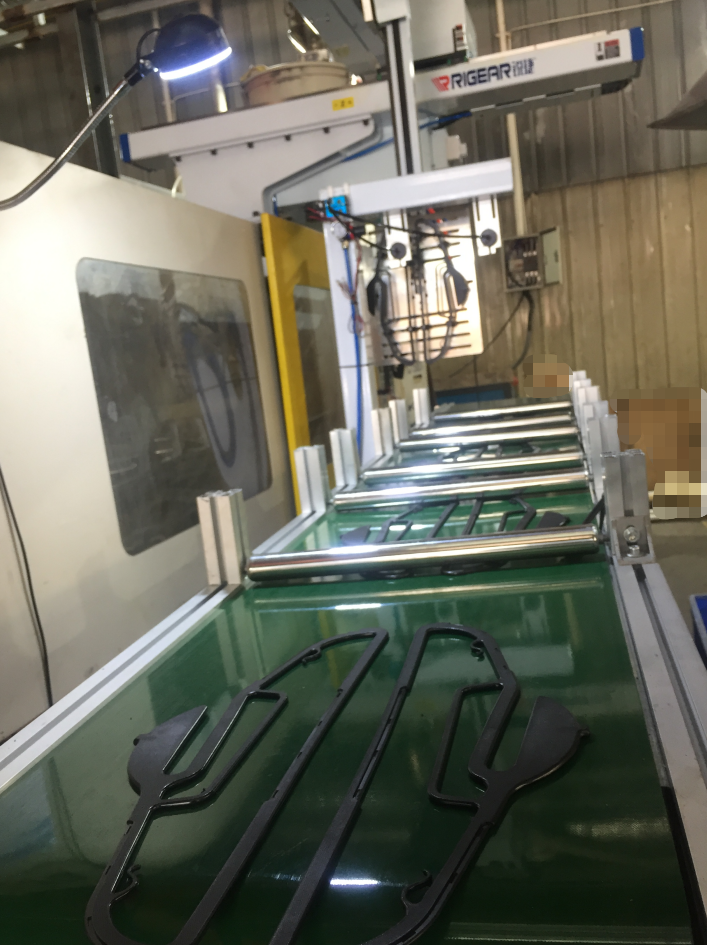

For market and customer demanding, our Hometime factory not only expanding new standard workshops,

but also using the manipulators to cooperate with our injection machines for our clothes hangers mass production.

It did improves our factory’s production efficiency.

Let’s talk about the advantages of the manipulators.

1. High safety: The use of the manipulator avoids the danger of hand injury due to injection molding machine failure or incorrect operation,

as well as industrial accidents caused by negligence or fatigue of workers. Especially for larger injection molding machines.

2. Stable cycle time: the output determines the long-term interests.

The same plant, the same equipment, and the same conditions, due to the stability of the production cycle, the use of robots will virtually increase the hangers output.

3. High efficiency: It can fix the production time of each mold product, and the same plasticizing time, injection time, pressure holding time, cooling time,

and mold opening and closing time can easily improve the yield of the product.

4.Save raw materials: The time for personnel to take out is uncertain,which may cause product shrinkage and deformation

(if the material tube is overheated, it will waste raw materials if it needs to be re-injected).

The manipulator takes out at a fixed time, so the quality is stable.

5. Prevent mold damage: If the worker fails to take out the plastic clothes hangers successfully, the mold clamping will cause damage to the mold.

If the manipulator fails to take out the coat hangers successfully, it will automatically alarm and stop.

6. Labor saving: The manipulator takes out the product and places it on the conveyor belt or the receiving table.

Only one person needs to take care of it or one person can watch two or more injection molding machines at the same time, which can save labor.

7. Improve product quality: The manipulator adopts non-pattern suction cups to exert even force, the clamping time is fixed, and the mold temperature is normal,

which can reduce the defect rate of products and greatly improve the quality of products.

8. Improve competitiveness: use manipulators to improve the image of the workshop,

ensure the quality, more accurately calculate the output, and enhance the competitiveness of the enterprise.

Welcome to contact us for any business discussion.Email : carey@hometimefactory.com

Post time: Jun-17-2022